Aufbau Filtersysteme

Function and construction of the filter system

Das Filtersystem besteht im Regelfall aus einem Partikelfilter und einem Aktivkohlefilter. Während der Partikelfilter alle festen Verunreinigungen vom großen Laubblatt bis hin zu kleinsten Feinstaubpartikeln aus der Luft entfernt, verringert der Aktivkohlefilter die Konzentration gasförmiger Luftschadstoffe wie Stickstoffdioxid, Ozon und Benzol.

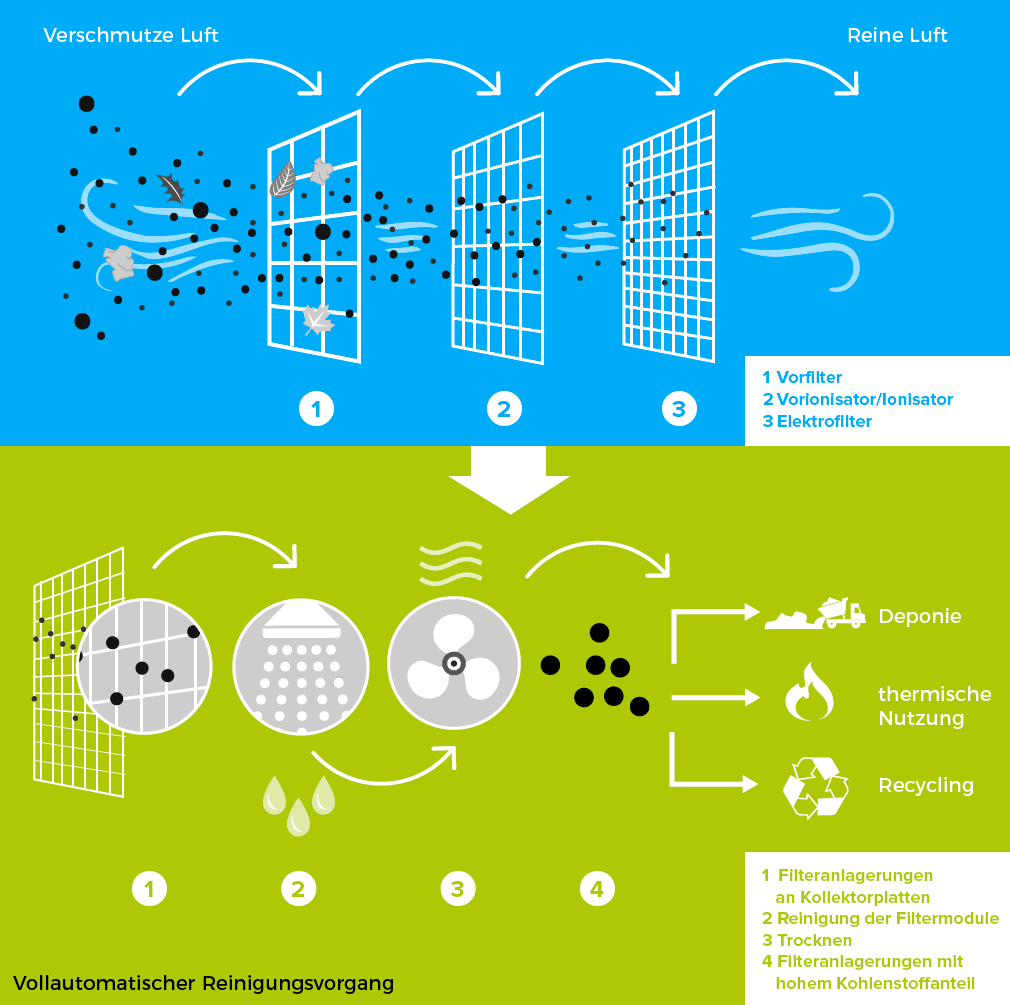

Pre-filter

Firstly, larger particles such as leaves and coarse dust are retained in the pre-filter. This protects the downstream electrostatic precipitator and increases its efficiency.

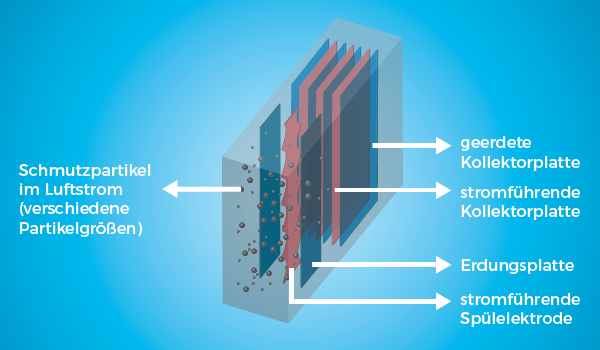

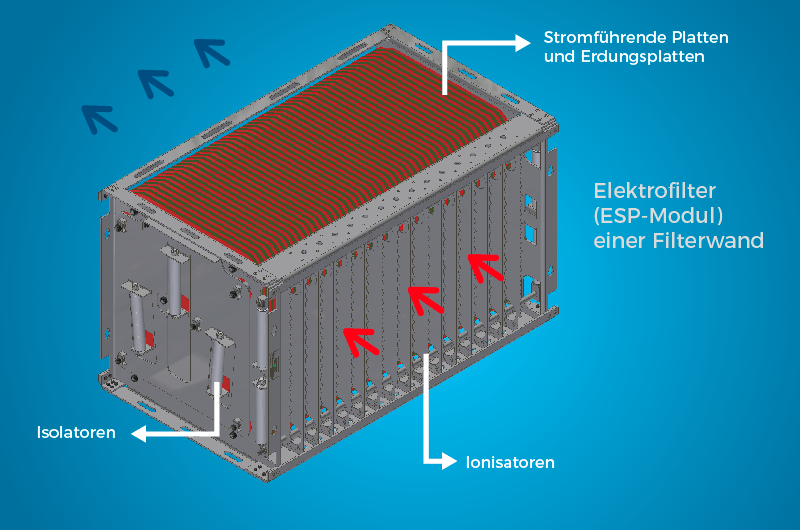

Two-stage electrostatic precipitator

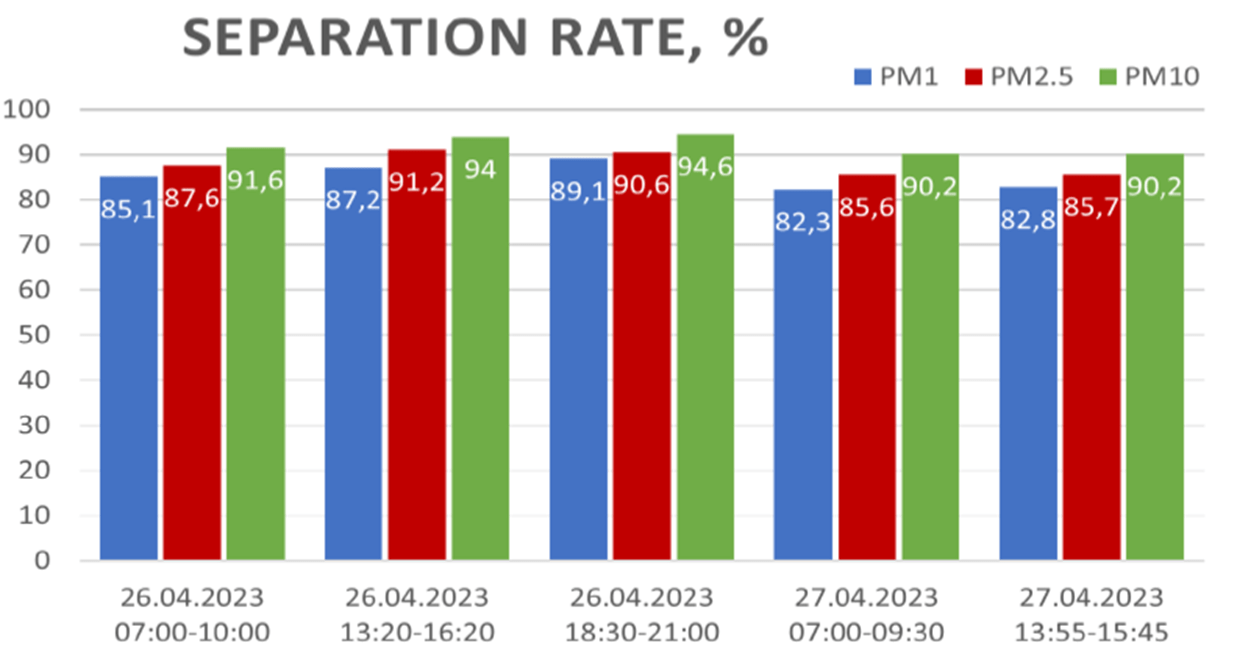

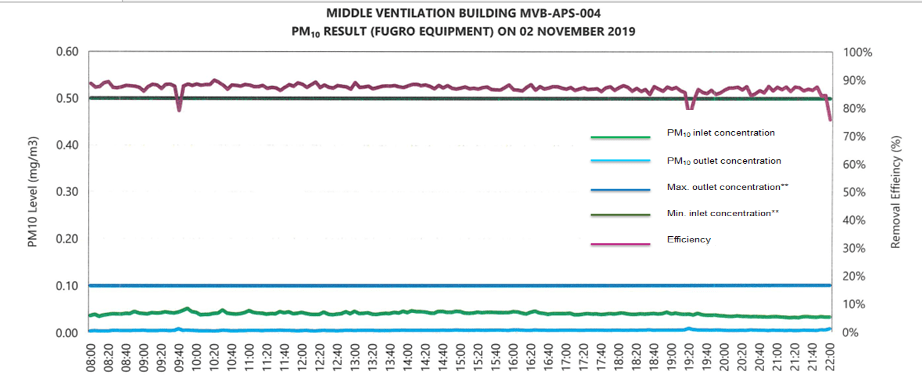

The air then flows through a two-stage electrostatic precipitator, consisting of an ioniser and a collector. The fine dust and soot particles contained in the air flow are electrically charged in the ioniser. These are then deposited on the collector, where they are effectively separated. The electrostatic precipitator removes more than 85 % of the harmful particles, including the respirable and particularly harmful PM1-particles.

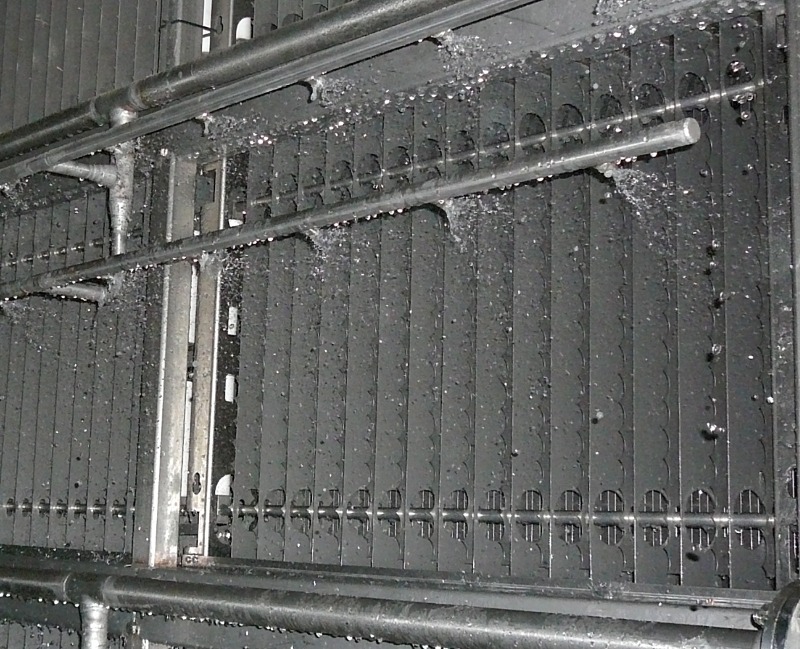

Automatic cleaning of the filter plates

The collector plates loaded with fine dust are cleaned automatically on a regular basis. The plates are rinsed with water via spray nozzles. During the cleaning process, the filter modules are de-energised to ensure safe operation.

Depending on the system configuration, either compressed air is used to dry the electrostatic precipitators or - even more resource-efficient - the natural air flow during operation. In this case, a specially developed soft start algorithm ensures a smooth restart without the need for an additional compressed air system. This saves both investment and operating costs.

Cleaning is fully automatic, takes around 30 minutes and is preferably carried out at night when there is little traffic in order to minimise disruption to operations.

Sustainable water treatment and safe disposal

The wash water produced during cleaning is purified in an integrated water treatment system. This removes the deposited particles so that over 90 % of the water can be reused for the cleaning process. This significantly reduces fresh water consumption and supports sustainable system operation.

The separated residues can be discharged with the tunnel wastewater or fed into the local wastewater treatment plant, as they do not contain any toxic substances and chemically correspond to the composition of road runoff that occurs during rainfall.

The entire filter process is designed to be environmentally friendly from the ground up. Unlike many conventional systems, the FILTRONtec process does not require any chemical additives or aids - for example to coagulate solids in the wash water. As a result, additional environmental pollution is avoided and operation remains sustainable, efficient, cost-effective and safe in the long term.

FILTRONtec stands for clean air - sustainable, efficient and fully automatic.

Capture of nitrogen dioxide and other harmful gases

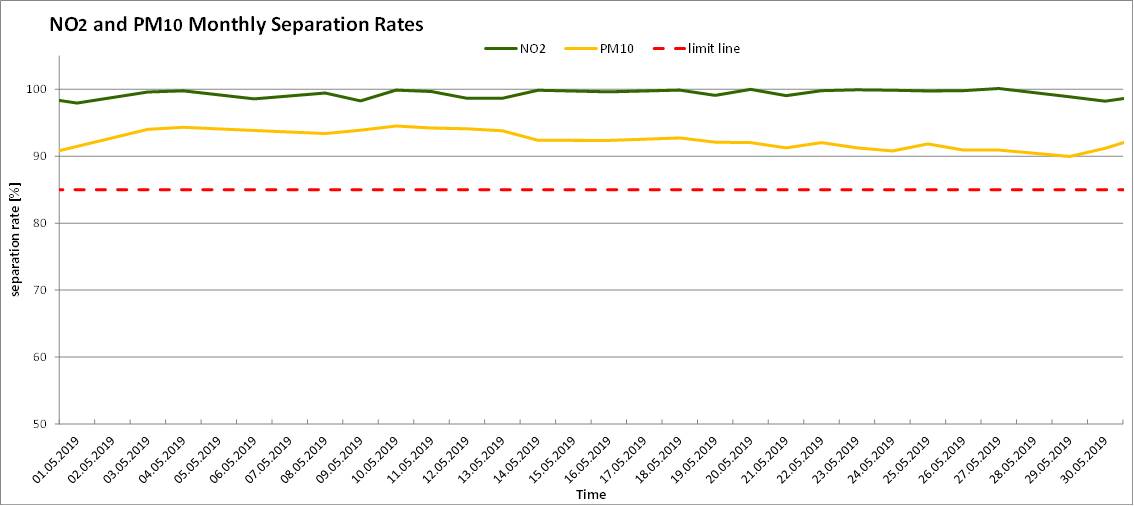

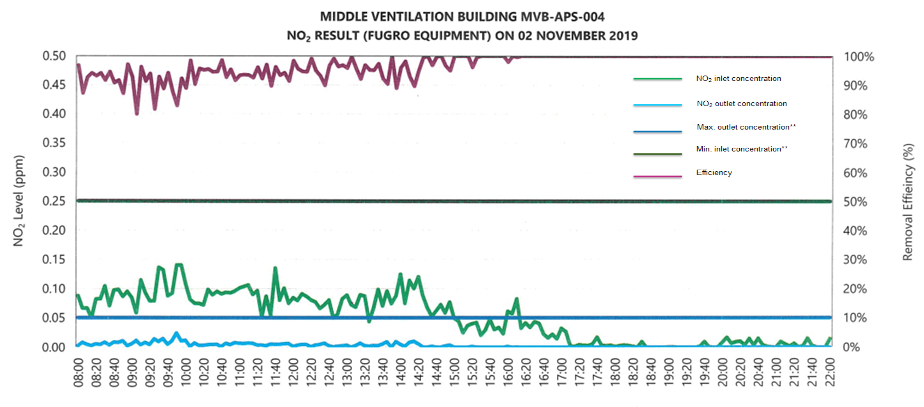

To reduce gaseous pollutants such as nitrogen dioxide (NO₂), unburnt hydrocarbons (CmHn), ozone (O₃) and benzene, an activated carbon filter can be installed downstream of the fine dust filter. This removes up to 90 % of the harmful gases contained in the exhaust air and thus makes a significant contribution to air pollution control in tunnels and their surroundings.

The specially treated activated carbon has a very high adsorption capacity. Nitrogen dioxide is not only physically bound, but also catalytically converted into harmless nitrogen (N₂) and oxygen (O₂). The filter carbon is available in the form of cylindrical pellets or granules. Due to its highly porous structure, activated carbon has an enormous internal surface area - just one gram provides an active surface area of around 1,000 m².

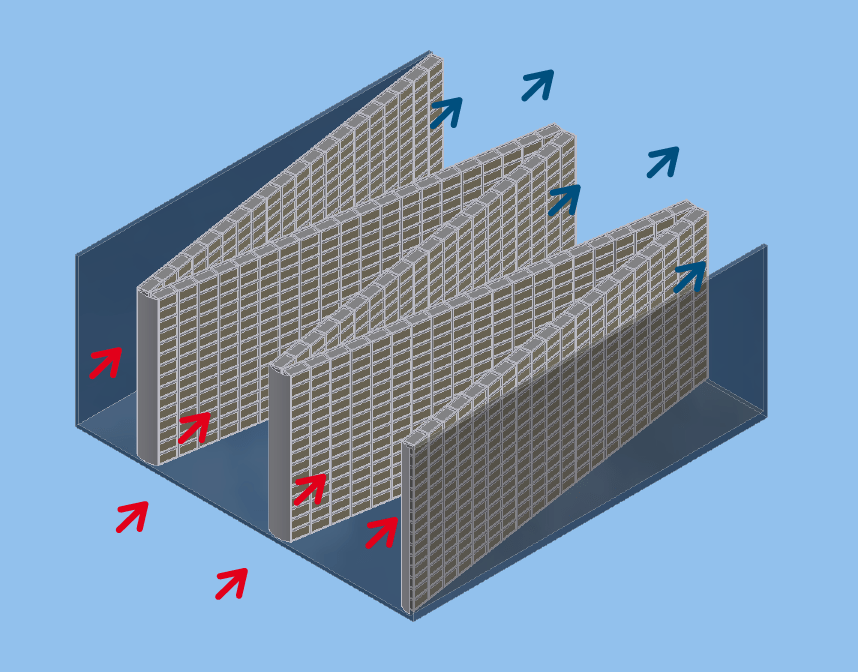

To ensure even air distribution and a high separation efficiency, the filter walls in the air duct are arranged in a W-shape.

If the separation capacity of the activated carbon is exhausted after several years of operation, it is simply replaced with a new one. This keeps the filter system permanently efficient - with minimal maintenance. The replaced carbon can be regenerated or reused in other applications.

Durable materials for high operational reliability

All components of the filter system that come into contact with the tunnel air - including electrostatic precipitators, pipework, spray nozzles and frames - are made of high-quality stainless steel (V4A). This corrosion-resistant material ensures a long service life and reliable operation even under demanding environmental conditions.

FILTRONtec offers customised solutions for the effective separation of harmful gases - robust, efficient and environmentally friendly.

Behaviour of the air filter in case of fire

A fire is the greatest risk in a tunnel. The suction effect causes fire and smoke to spread in a very short time, while temperatures quickly reach extreme levels due to the tight construction. In addition, thick smoke and toxic gases make evacuation, firefighting and rescue work more difficult - especially in tunnels that are getting longer and longer.

An efficient filter system can make a decisive contribution to safety in such a situation. The particle filters from FILTRONtec are designed to remain functional even at temperatures of up to 400 °C. In the event of a fire, the smoke gases can be channelled through the fine dust filter, which retains hazardous particles and pollutants for a limited period of time.

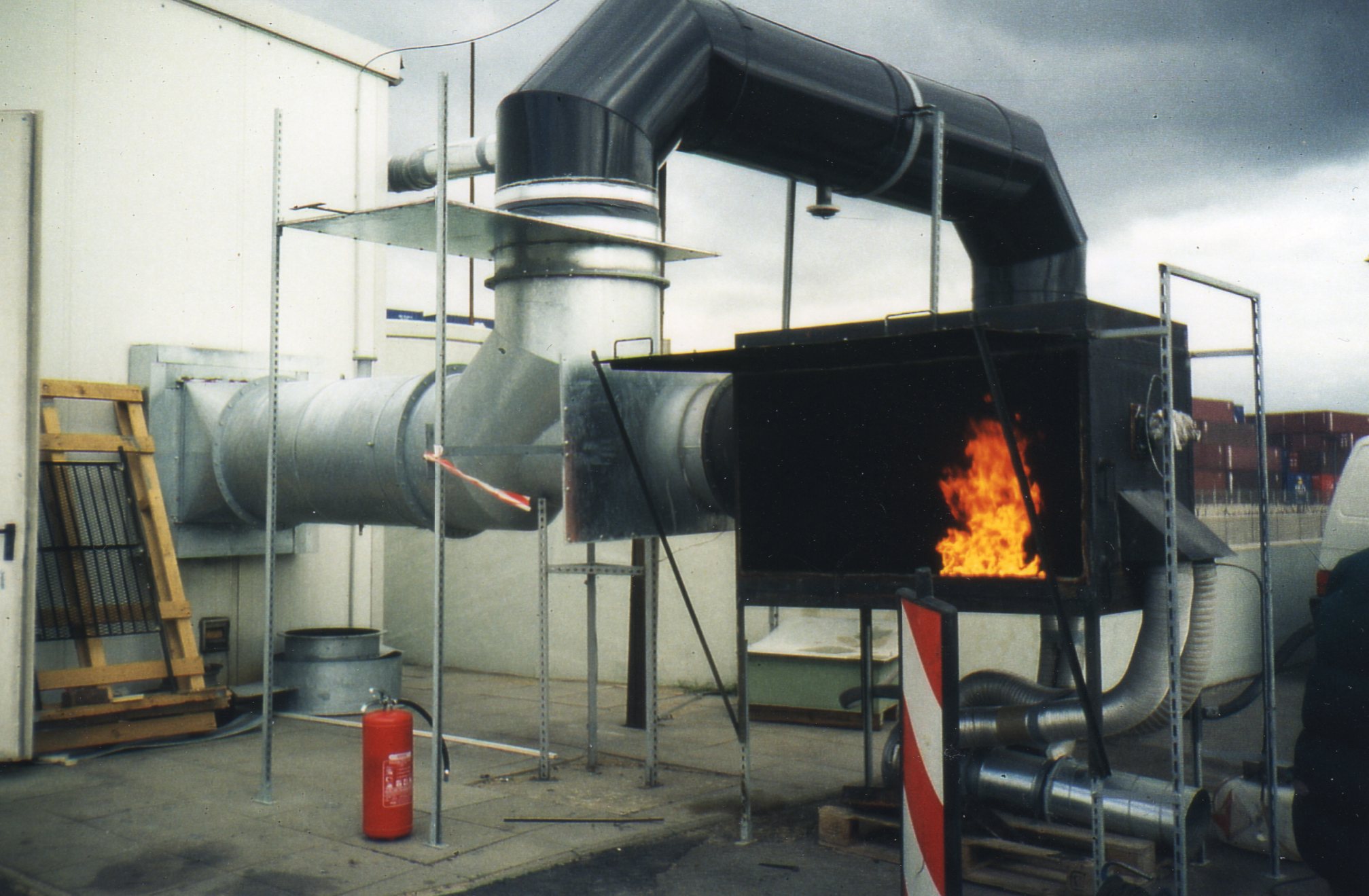

A fire test carried out impressively demonstrates the effectiveness of this technology: various materials such as oil, petrol, car tyres and vehicle interior parts were burnt in a test facility. The resulting flue gases were channelled through an electrostatic precipitator installed in an adjacent room. The subsequent measurements showed that the flue gas density and visual opacity could be reduced by around 80 %.

Improved visibility is particularly crucial in the first few minutes after a fire breaks out - it increases the chances of a successful evacuation and can therefore save lives.